Founders Brewing Co.

Welcome To Founders

We Have Something For Everyone

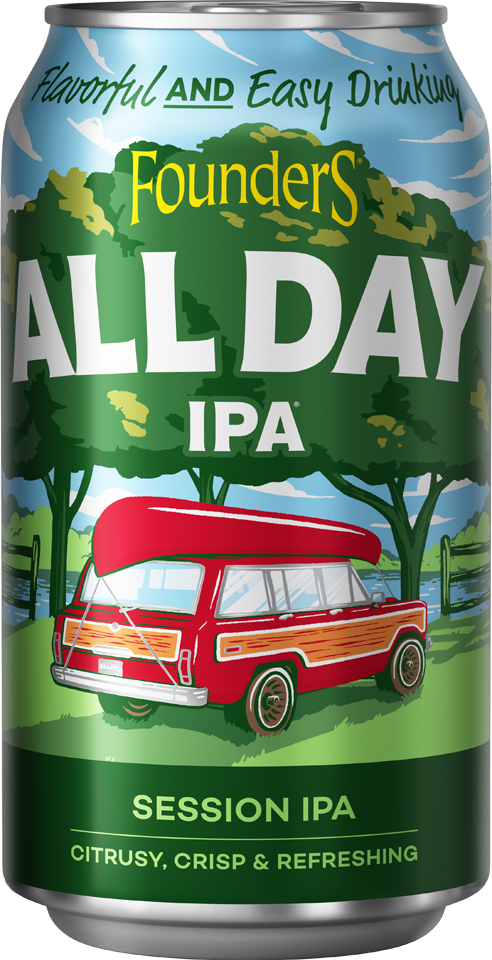

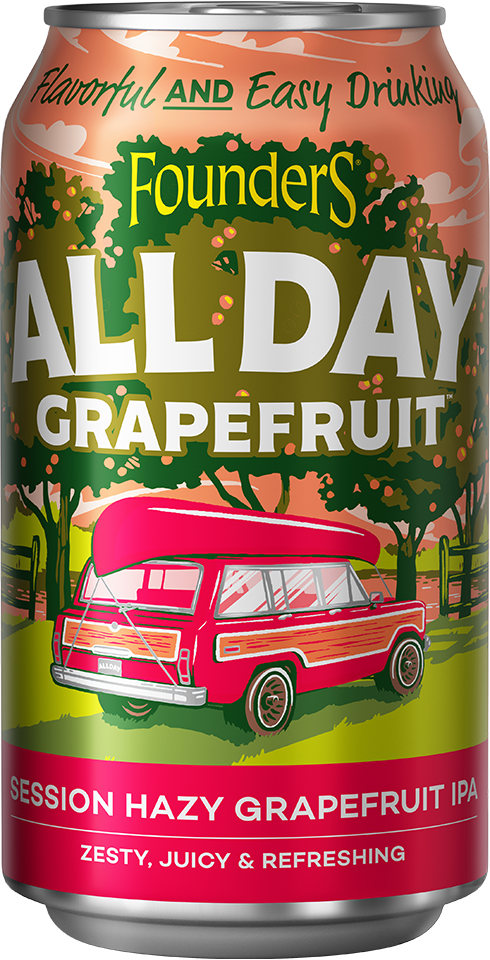

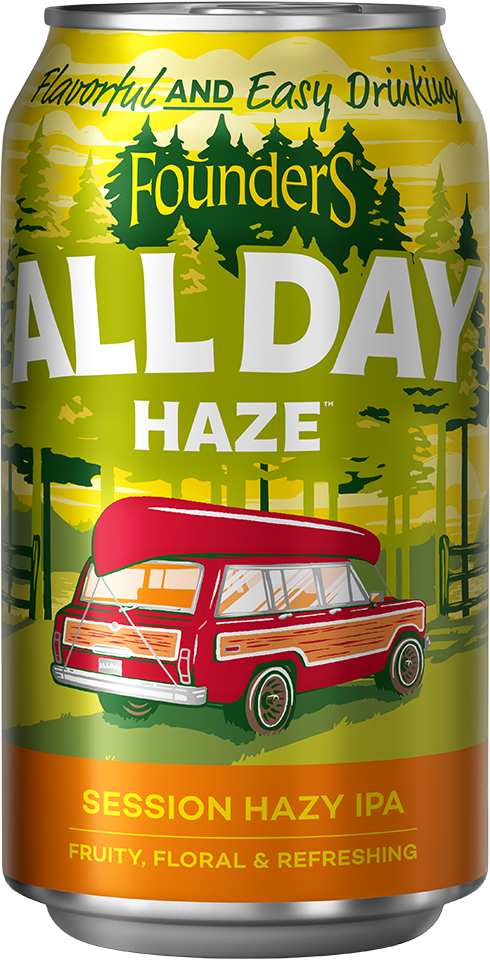

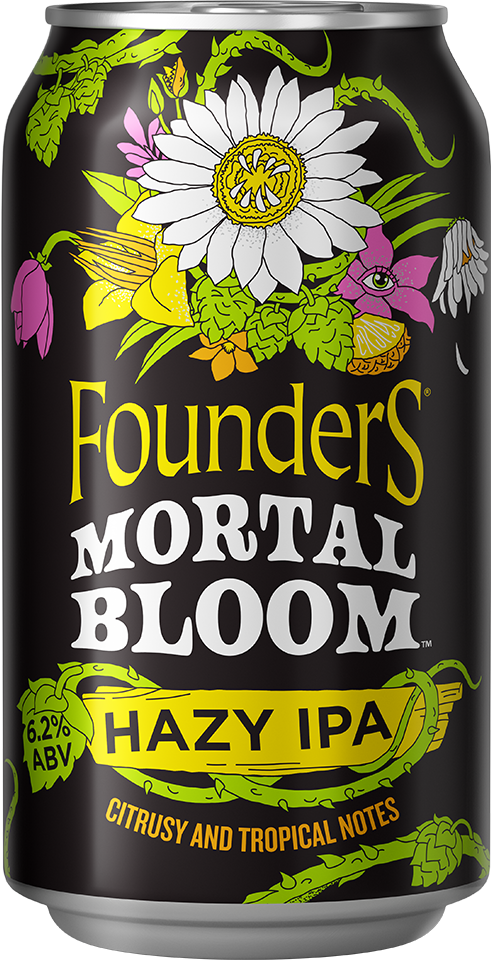

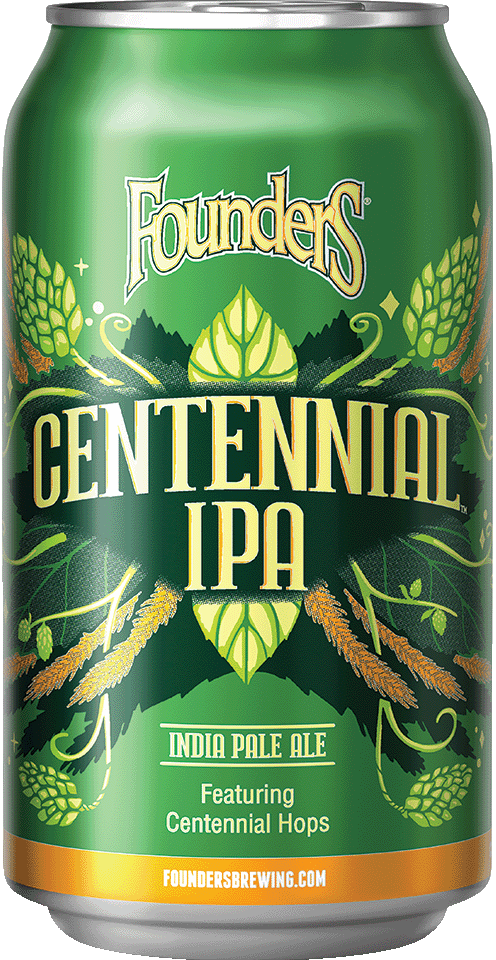

Our Beer

Grand Rapids Taproom

What’s Happening Today

Chirp

Visit us for HAPPY HOUR!

Receive $1 off of full pours of beer Monday through Friday from 2-5:30pm.